During Summer 2025 I reached out to the Boundary Layer Wing Tunnel at Western to see if clubs could gain access and how that process worked. This was a first for the Aero Design Team at Western and provided an opportunity to get hands on with a large-scale wind tunnel and the limitations of testing.

Who is Boundary Layer Wind Tunnel Laboratory

Boundary Layer Wind Tunnel Laboratory (BLWTL) is built and designed to access civil applications such as Skyscrapers, Bridges, or City Blocks. BLWTL has been employed to do analysis on various projects such as the CN Tower, and the Burj Khalifa.

How To Test

After confirming our ability to use the facilities, a plan on how to test our aircraft was required. Given that the tunnel was capable of a maximum of 20 m/s winds and a 3.4-meter wide by 2.5-meter-tall tunnel we were not able to test a full scall model of our aircraft. At a 3.048-meter wingspan we could technically fit inside the tunnel however the interference of the wind interacting both with the model but also the surrounding walls would cause invalid results that could not be relied on. Due to the tunnels relatively low wind speed we were unable to significantly scale down the model either.

As such the team went with a full-scale model of half the wing. at 1.525 meters this would limit interference with boundary layer wind in the tunnel surfaces and not require and increase in Wind Speed to maintain Reynolds number.

Roles

Myself (Josh Ray) - Organized visit and develop testing plan. Guided design and construction of test setup with assistance of BLWTL staff. Managed testing and data collection.

Harris Reid - Designed test setup and lead construction

Korsyn Pranger - Assisted in test setup construction and aided in facilitating efficient use of testing time.

Results

The results if this wind tunnel test were less than ideal. With a designed weight of 244 newtons the expectation was that at cruise speed the model would generate 120 newtons of lift force. However, only 60 newtons of lift force were measured.

Test Limitations

Sources of error that could lead to this large deviation from the expected lift could be the force sensor employed was the largest BLWTL had but was still not large enough for our use case. the bending moment measured by this for sensor was only 80 newton meters. the expectations were that our model could produce a bending moment of up to 150 newton meters at the upper limit of our testing plan. This limited the speeds and angle of attacks that could be tested at. As well even though this measure is not directly used to calculate the lift generated, due to the internal workings of the force sensor beyond my understanding the maxing out of one axis of measurement has an effect on all others as well. This could result in the average lift force measured being “pulled down” by the maxing of this other measurement.

Significant buffeting was also observed during testing which could result in a measurement not representative of real-world performance.

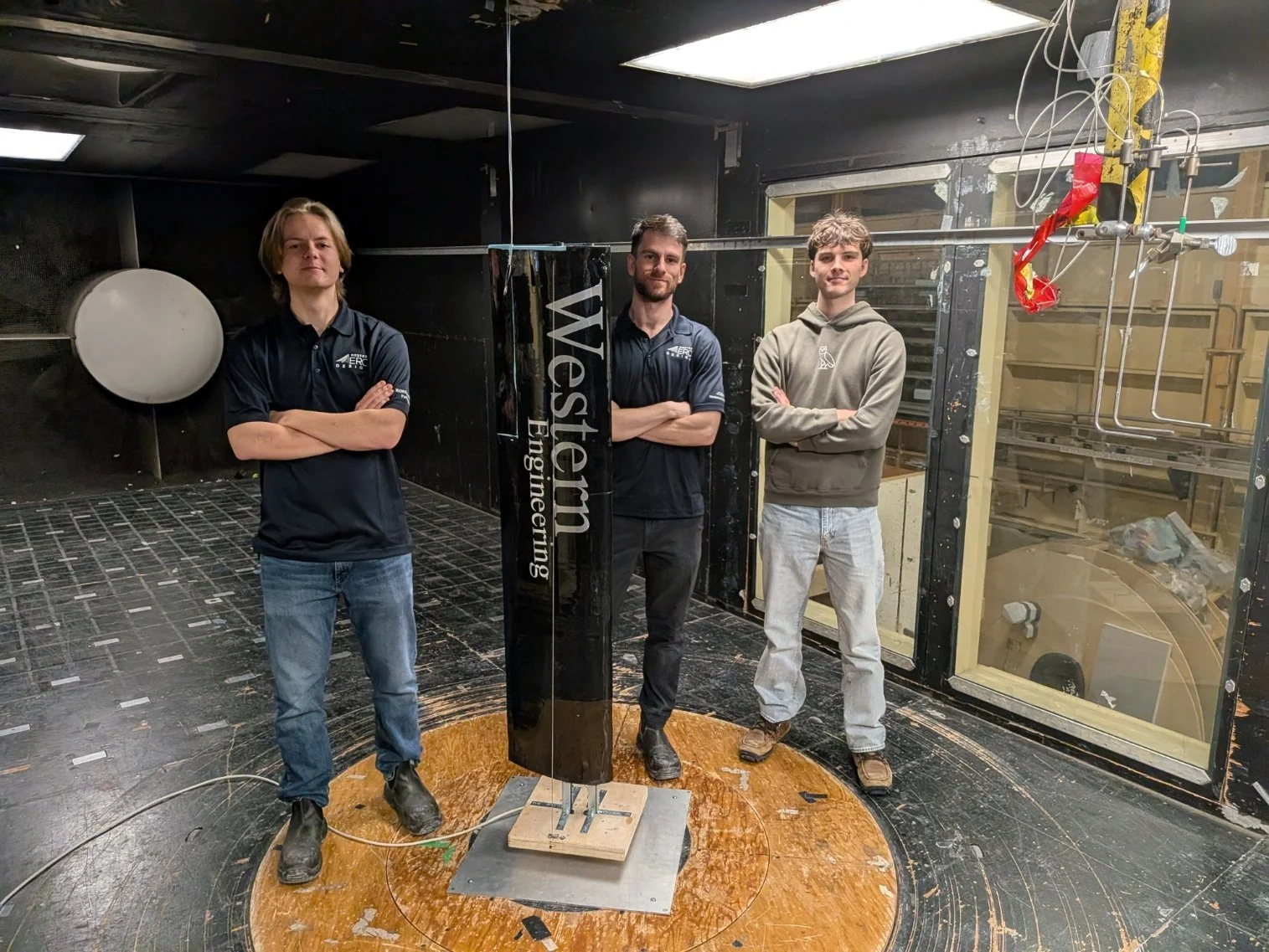

Left to Right:

Korsyn Pranger - Fuselage Lead

Myself (Josh Ray) - Wing & Project Lead

Harris Reid - Test Model Lead